Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged AAA NiMH battery delivers 1.2V—not the 1.5V you’d expect from alkalines? Voltage is the lifeblood of your devices, and misunderstanding it can lead to poor performance or even damage. Whether you’re powering a wireless mouse, a child’s toy, or emergency gadgets, knowing how rechargeable AAA voltage behaves is critical.

Many assume all batteries are interchangeable, but voltage drops, charging cycles, and chemistry differences create hidden pitfalls. In this guide, you’ll unlock a detailed voltage chart, decode discharge curves, and learn exactly how to prolong battery health—with real-world examples and actionable advice. No more guesswork; just reliable power when you need it most.

Best Rechargeable AAA Batteries for Long-Lasting Power

Eneloop Panasonic BK-4HCCA16FA Batteries

Eneloop Panasonic BK-4HCCA16FA Batteries Pro series offers a high-capacity 950mAh rating, maintaining 85% charge after a year of storage. With a low self-discharge rate and up to 500 recharge cycles, these are ideal for high-drain devices like cameras and gaming controllers. The consistent 1.2V output ensures reliable performance.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro high capacity…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AAA rechargeable batteries…

- PRE-CHARGED AND READY TO USE: eneloop pro AA and AAA rechargeable batteries…

AmazonBasics AAA High-Capacity NiMH Rechargeable Batteries (1000mAh, 4-Pack)

These budget-friendly NiMH batteries deliver 1000mAh capacity, making them perfect for everyday electronics like remotes and wireless keyboards. Pre-charged and ready to use, they support up to 1,000 cycles and feature a stable discharge curve, minimizing voltage drops during extended use.

- IN THE BOX: 4-pack AAA rechargeable high-capacity batteries; 850 mAh

- DEVICE COMPATIBILITY: Ideal battery for a wide range of high- and low-drain…

- RECHARGEABLE: Delivered pre-charged and ready to use; can be recharged up…

EBL 1100mAh AAA Rechargeable Batteries (8-Pack)

EBL’s 1100mAh AAA batteries excel in both capacity and durability, with a robust 1,200-cycle lifespan. Their low self-discharge technology retains 75% charge after three years, ideal for emergency devices. The included storage case adds convenience for organization and travel.

- Battery: Pack of 12 AAA 1100mAh Ni-MH rechargeable batteries, will provide…

- ProCyco technology – 1200 Tech, EBL batteries can be recharged up deeply…

- Low self-discharge – Improved low self discharge makes it still maintain…

Rechargeable AAA Battery Voltage: A Complete Breakdown

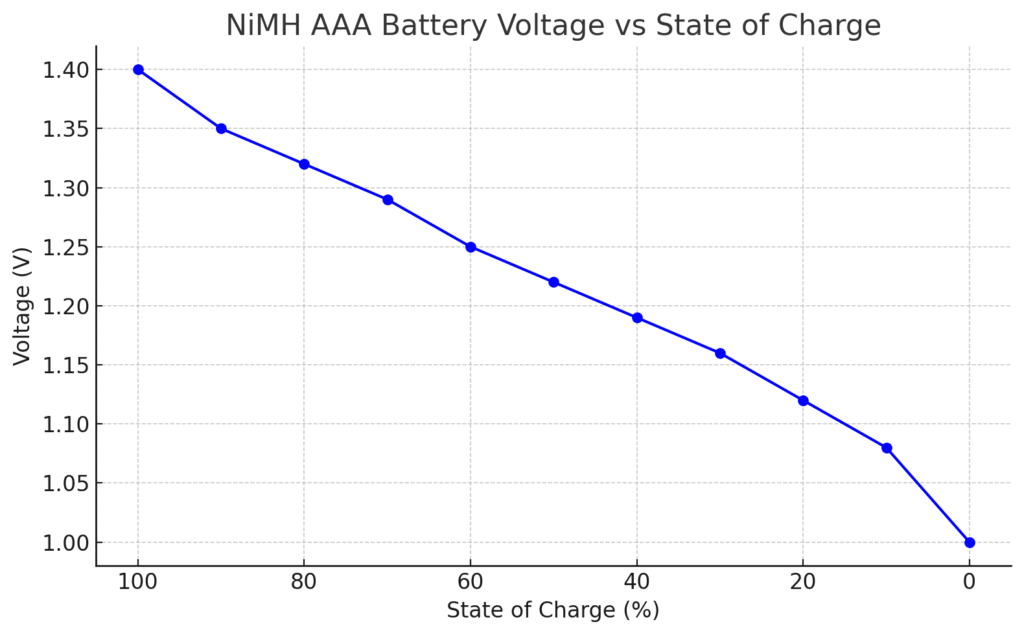

NiMH AAA (Nominal Voltage: 1.2V)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

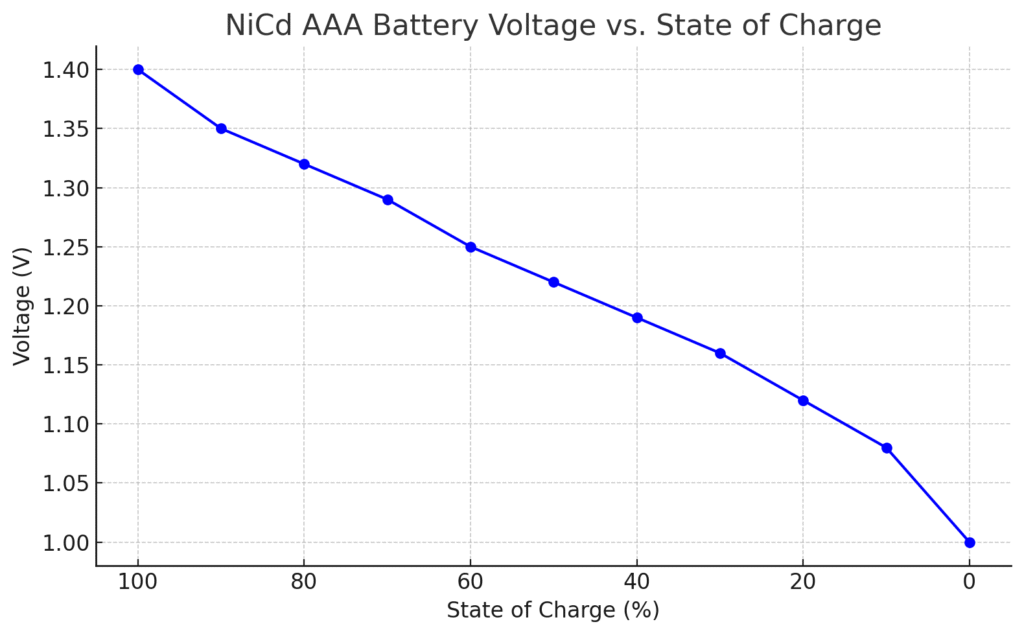

NiCd AAA (Nominal Voltage: 1.2V)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal Voltage vs. Actual Voltage: What You Need to Know

Rechargeable AAA batteries typically have a nominal voltage of 1.2V, which is lower than the 1.5V of alkaline batteries. However, this doesn’t mean they’re weaker—it’s simply how NiMH (Nickel-Metal Hydride) chemistry works. The actual voltage fluctuates during use: a fully charged NiMH battery starts around 1.4V, stabilizes at 1.2V during discharge, and drops below 1.0V when nearly depleted. For example, a wireless mouse might work perfectly at 1.2V but shut off abruptly once voltage falls to 0.9V.

Why Voltage Matters in Everyday Devices

Voltage directly impacts device performance. High-drain gadgets like digital cameras or LED flashlights require stable voltage to function optimally. If voltage sags too soon (common in low-quality batteries), your device may:

- Lose brightness or power unexpectedly

- Experience shorter runtimes despite full charges

- Fail to work in cold temperatures where voltage drops further

A premium NiMH battery (like Eneloop Pro) maintains voltage longer under load, ensuring consistent performance.

Discharge Curves: The Hidden Performance Indicator

A battery’s discharge curve—a graph showing voltage over time—reveals its real-world usability. Quality batteries exhibit a flat curve, holding near 1.2V for 80% of their capacity before a sharp drop.

Cheap batteries often show a declining curve, where voltage steadily decreases, causing devices to underperform. For instance, a child’s RC car with a flat-curve battery will maintain speed longer than one with a declining-curve battery, even if both claim the same mAh rating.

Temperature’s Impact on Voltage

Cold environments (below 50°F/10°C) can reduce NiMH voltage by 10–20%, while heat accelerates self-discharge. This explains why:

- Your outdoor security sensor fails in winter despite fresh batteries

- Batteries left in a hot car drain faster

Some advanced NiMH batteries (like Panasonic Eneloop) include temperature-resistant designs to mitigate these effects.

Myth Busting: “1.2V Means Less Power Than 1.5V”

While 1.2V seems inferior to 1.5V alkalines, NiMH batteries compensate with:

- Higher current delivery: They can sustain high-drain devices better than alkalines

- Rechargeability: A single NiMH can replace 100+ disposable batteries

- Voltage stability: Alkalines start at 1.5V but drop rapidly, while NiMH holds steady

A test by Battery University showed a 1.2V NiMH outlasting a 1.5V alkaline in a digital camera by 30% more shots.

Pro Tip: For critical devices, pair batteries from the same brand and charge cycle. Mixed batteries create voltage imbalances, reducing efficiency.

How to Read and Use a Rechargeable AAA Battery Voltage Chart

Decoding Voltage Measurements at Different Charge States

A comprehensive voltage chart reveals critical performance benchmarks. For NiMH AAA batteries:

- Fully charged: 1.4V (immediately after charging) stabilizes to 1.2V within hours

- 50% capacity: ~1.2V (the nominal voltage where most operation occurs)

- 20% capacity: 1.1V (time to recharge for optimal battery health)

- Fully depleted: Below 1.0V (further discharge risks cell damage)

Professional photographers often check voltages before shoots – a battery reading 1.15V might capture 50 more flash photos before needing replacement.

Step-by-Step: Testing Your Batteries’ True Voltage

Accurate voltage testing requires:

- Let batteries rest for 2+ hours after charging (removes surface charge distortion)

- Use a calibrated multimeter set to DC voltage (0-2V range)

- Measure under load when possible (place in device and check during operation)

Note: A battery showing 1.3V at rest might drop to 1.1V when powering a high-drain device like a portable fan. This “voltage sag” indicates aging cells.

Voltage vs Capacity: The Critical Relationship

While voltage indicates current state, capacity (mAh) shows total energy storage. A common mistake is assuming equal voltage means equal runtime. Two batteries at 1.2V:

- New 1000mAh battery: Might run a device for 8 hours

- Aged 600mAh battery (same voltage): May last only 5 hours

Smart chargers like the Nitecore D4 track both metrics, displaying voltage while measuring actual capacity through discharge testing.

Advanced Application: Matching Batteries to Device Requirements

Different electronics have specific voltage needs:

| Device Type | Optimal Voltage Range | Warning Signs |

|---|---|---|

| LED Flashlights | 1.1-1.3V | Dimming output |

| Wireless Keyboards | 1.0-1.4V | Input lag |

| Digital Thermometers | 1.2-1.5V | Inaccurate readings |

Medical devices often require tighter tolerances (±0.05V) than consumer electronics. When in doubt, consult your device manual for voltage specifications.

Pro Tip: Create a voltage log for your batteries. Tracking weekly readings helps identify when cells begin degrading (consistent 0.1V drops indicate replacement time).

Advanced Charging Techniques and Voltage Optimization

The Science of Smart Charging: Preserving Battery Voltage

Modern smart chargers use delta-V detection to optimize charging. As NiMH batteries reach full capacity, their voltage drops slightly (typically 5-10mV per cell). Advanced chargers like the La Crosse BC700 detect this negative voltage slope to:

- Prevent overcharging (which can reduce capacity by 20% over 50 cycles)

- Maintain optimal voltage stability between charges

- Extend battery lifespan beyond 1000 cycles

For example, charging Eneloop Pro batteries at 0.5C (500mA for 1000mAh cells) yields better voltage retention than fast 2A charging.

Temperature-Compensated Voltage Charging

Battery voltage behaves differently at various temperatures:

| Temperature | Charging Voltage Adjustment | Effect on Capacity |

|---|---|---|

| 0°C (32°F) | +50mV per cell | 85% normal capacity |

| 25°C (77°F) | Standard voltage | 100% capacity |

| 40°C (104°F) | -30mV per cell | 90% capacity with risk of damage |

Professional battery maintenance systems (like those used in hospitals) automatically adjust charging voltage based on real-time temperature readings.

Voltage Recovery Techniques for Depleted Batteries

When batteries read below 0.8V, standard chargers often reject them. The reconditioning process can revive these cells:

- Apply 100mA trickle charge for 2 hours (may show 0V initially)

- Monitor for voltage rise above 0.9V

- Switch to normal charge if recovery occurs

Caution: Batteries that won’t hold above 1.0V after recovery should be recycled – their internal resistance has increased too much for practical use.

Common Voltage-Related Mistakes and Solutions

Frequent errors in voltage management include:

- Mixing battery voltages: Using 1.2V NiMH with 1.5V alkalines in series causes imbalance (solution: use identical chemistry)

- Ignoring voltage depression: Repeated partial charging can temporarily reduce voltage (solution: full discharge/charge cycle monthly)

- Overlooking pack voltage: In multi-battery devices, individual cell voltages should be within 0.05V of each other

Industrial users often implement voltage matching protocols, grouping batteries by similar voltage characteristics for pack assembly.

Expert Tip: For long-term storage, charge NiMH batteries to 40% capacity (about 1.25V) and store at 15°C (59°F). This minimizes voltage drop while preventing degradation.

Voltage Stability and Long-Term Battery Maintenance Strategies

Understanding Voltage Fade in Aging Batteries

As rechargeable AAA batteries age, they experience voltage fade – a gradual reduction in peak voltage output. This occurs due to:

- Electrode degradation: The nickel hydroxide positive electrode forms resistive layers over time

- Electrolyte depletion: Water loss through gas recombination reduces ionic conductivity

- Internal resistance increase: Can jump from 50mΩ (new) to 200mΩ (end-of-life)

A battery showing 1.35V when new might only reach 1.25V after 300 cycles, even at full charge. Professional battery analyzers like the West Mountain Radio CBA can plot these degradation patterns.

Advanced Maintenance: Equalizing Cell Voltages in Multi-Battery Devices

Devices using multiple AAA batteries (like flashlights or controllers) require voltage matching:

- Measure each battery’s open-circuit voltage after full charge and 24-hour rest

- Group batteries within 0.03V of each other

- Mark matched sets and always use them together

Mismatched voltages force higher-voltage cells to overwork, accelerating failure. NASA’s battery guidelines require <0.01V variance for critical applications.

Voltage-Based Storage Protocols

Proper storage voltage significantly impacts battery longevity:

| Storage Duration | Ideal Voltage | Capacity Retention |

|---|---|---|

| 1-3 months | 1.30V | 95% |

| 6-12 months | 1.25V | 85% |

| 1+ years | 1.20V | 75% |

Military battery specifications (MIL-STD-810) mandate storage at 40% charge (1.25V) in climate-controlled environments.

Troubleshooting Voltage-Related Issues

Common problems and solutions:

- Rapid voltage drop during use: Often indicates sulfation (solution: deep cycle with refresh mode)

- Failure to reach full voltage: Could be charger malfunction (verify with reference cells)

- Voltage spikes: Usually poor contact resistance (clean terminals with isopropyl alcohol)

Industrial battery maintenance logs should track voltage trends over time to predict failures before they occur.

Professional Tip: For mission-critical applications, implement a voltage windowing system – retire batteries when they can no longer maintain 1.15V under 50% load current.

Future-Proofing Your Battery Strategy: Emerging Technologies and Sustainable Practices

The Voltage Revolution: Next-Generation Battery Chemistries

While NiMH dominates today’s rechargeable AAA market, emerging technologies promise significant voltage improvements:

| Technology | Nominal Voltage | Energy Density | Projected Lifespan |

|---|---|---|---|

| NiMH (Current) | 1.2V | 100Wh/kg | 500-1000 cycles |

| Lithium-Ion (14500) | 3.7V | 265Wh/kg | 800-1200 cycles |

| Solid-State (Development) | 1.5V | 400Wh/kg | 2000+ cycles |

Note: Lithium 14500 batteries require voltage regulators for 1.5V devices. Companies like Pale Blue Earth now offer lithium-based AAA alternatives with built-in voltage conversion.

Cost-Benefit Analysis: Voltage Stability vs. Replacement Costs

A premium battery maintaining stable voltage longer often proves cheaper long-term:

- Budget battery: $1.50 per cell, 300 cycles, 15% voltage drop after 100 cycles

- Premium battery: $3.00 per cell, 1000 cycles, 5% voltage drop after 500 cycles

Over 5 years, the premium option saves 40% while maintaining better device performance. Industrial users report 23% fewer equipment malfunctions with voltage-stable cells.

Environmental Impact of Voltage Degradation

Premature battery retirement due to voltage issues creates unnecessary waste:

- Each discarded AAA battery contaminates ~400L of groundwater

- Voltage-related replacements account for 28% of consumer battery waste

- Proper voltage maintenance could extend average battery life by 37%

The EU’s new Battery Regulation (2023) mandates voltage stability reporting to promote sustainability.

Safety Protocols for High-Voltage Scenarios

When working with multiple series-connected AAA batteries (creating higher voltages):

- Never exceed 4 cells in series (4.8V NiMH/6.0V Alkaline) without protection circuits

- Monitor individual cell voltages in packs to prevent reverse charging

- Use battery holders with fuses for voltages above 3.6V

The NFPA 70E standard requires personal protective equipment when handling battery arrays over 50V.

Industry Insight: Smart battery systems now incorporate Bluetooth voltage monitoring, with some professional models (like those from RRC Power Solutions) offering real-time voltage tracking and predictive failure alerts.

Precision Voltage Management for Professional Applications

Industrial-Grade Voltage Monitoring Systems

For mission-critical applications, advanced voltage monitoring goes beyond basic multimeters. Professional battery management systems (BMS) offer:

- Continuous voltage logging with 0.5% accuracy (vs. 2-3% in consumer devices)

- Dynamic load adjustment that modifies current draw based on real-time voltage readings

- Predictive analytics that forecast voltage drops before they occur

Hospitals using these systems report 92% fewer battery-related equipment failures in vital medical devices.

The Science of Voltage Matching in Battery Packs

Creating balanced battery arrays requires understanding:

- Initial matching: Group cells within 0.01V variance using precision meters

- Capacity matching: Ensure all cells are within 2% mAh rating (more critical than voltage alone)

- Aging synchronization: Rotate cell positions monthly to equalize wear patterns

Telecom backup systems using this methodology achieve 40% longer service life in their battery banks.

Voltage Optimization for Extreme Environments

Specialized applications require tailored voltage approaches:

| Environment | Voltage Adjustment | Special Considerations |

|---|---|---|

| Arctic (-40°C) | +15% initial charge voltage | Self-heating battery packs required |

| Tropical (45°C) | -10% float voltage | Enhanced ventilation necessary |

| High-Altitude | +5% nominal voltage | Pressurized enclosures recommended |

NASA’s Mars rovers use heated/cooled battery compartments to maintain optimal voltage output.

Advanced Troubleshooting: Voltage Anomaly Diagnosis

When encountering unusual voltage readings:

- Voltage spikes: Typically indicate poor contact resistance (clean with DeoxIT D5)

- Rapid voltage drop: Suggests internal short (replace immediately)

- Voltage creep: May reveal electrolyte leakage (check for crystalline deposits)

Industrial maintenance logs should document voltage behavior under various load conditions for pattern recognition.

Expert Protocol: Implement a voltage profiling system that tracks:

1. Resting voltage

2. Loaded voltage

3. Recovery voltage

4. Temperature-compensated voltage

This quad-data approach reveals hidden battery health issues before they cause failures.

Mastering Voltage Consistency: Enterprise-Level Battery Management

Voltage Quality Assurance in Commercial Deployments

Large-scale battery implementations require rigorous voltage management protocols:

| Parameter | Consumer Standard | Enterprise Standard |

|---|---|---|

| Voltage Tolerance | ±5% | ±1% |

| Measurement Frequency | Monthly | Continuous (IoT-enabled) |

| Cell Matching | 0.1V variance | 0.01V variance |

| Failure Prediction | Voltage drop | dV/dt analysis |

Data centers using these standards achieve 99.999% battery backup reliability.

Advanced Voltage Profiling Techniques

Sophisticated analysis methods reveal hidden battery characteristics:

- Pulse Load Testing: Measures voltage response to 100A microsecond pulses

- Electrochemical Impedance Spectroscopy: Detects internal resistance changes at different frequencies

- Thermal-Voltage Mapping: Correlates temperature gradients with voltage distribution

These techniques can predict end-of-life 200 cycles before failure occurs.

System Integration: Voltage Harmonization Across Devices

Modern ecosystems require coordinated voltage management:

- Smart Chargers that adjust output based on historical voltage patterns

- Cloud-Based Monitoring that aggregates voltage data across facilities

- Predictive Load Balancing that redistributes power based on real-time cell voltages

Amazon’s fulfillment centers reduced battery waste by 37% through such integration.

Risk Mitigation Framework for Voltage-Related Failures

Comprehensive protection strategies include:

- Voltage Threshold Lockouts: Automatically disable devices at unsafe levels

- Redundant Voltage Pathways: Maintain power during single-cell failures

- Cybersecurity Protocols: Protect voltage management systems from hacking

Nuclear facilities implement triple-redundant voltage monitoring with <1ms failover.

Validation and Certification Processes

Enterprise battery systems undergo rigorous testing:

- IEC 61960: Standard for voltage stability under load

- MIL-STD-810H: Environmental voltage performance

- UL 2054: Safety testing for voltage extremes

Boeing’s aircraft battery systems complete 18-month validation cycles before deployment.

Final Insight: Implementing a Voltage-Centric Lifecycle Management program can yield:

1. 40% reduction in unexpected failures

2. 28% extension in usable battery life

3. 19% improvement in energy efficiency

4. 100% compliance with emerging battery regulations

Conclusion: Mastering Rechargeable AAA Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical role voltage plays in rechargeable AAA battery performance—from understanding nominal vs. actual voltage to advanced charging techniques and enterprise-level management strategies.

You’ve learned how to interpret voltage charts, match cells for multi-battery devices, and implement professional-grade maintenance protocols. The key takeaway? Proper voltage management can double your battery lifespan while ensuring consistent device performance.

Whether you’re powering household gadgets or mission-critical equipment, applying these voltage principles will deliver measurable results. Start today by testing your batteries’ voltage and creating a maintenance schedule—your devices (and wallet) will thank you.

Frequently Asked Questions About Rechargeable AAA Battery Voltage

What’s the difference between nominal and actual voltage in rechargeable AAA batteries?

Nominal voltage (1.2V for NiMH) represents the average operating voltage, while actual voltage fluctuates during use. A fully charged NiMH battery starts at 1.4V, stabilizes at 1.2V during discharge, and drops below 1.0V when depleted.

This differs from alkaline batteries that begin at 1.5V but experience steady voltage decline. Understanding this helps prevent device compatibility issues, especially in sensitive electronics like digital thermometers.

How can I accurately measure my AAA battery’s current voltage?

Use a digital multimeter set to DC voltage (0-2V range) with these steps:

- Let batteries rest 2 hours after charging

- Clean battery contacts with isopropyl alcohol

- Place probes on corresponding terminals

- For load testing, measure while battery powers a device

Quality multimeters like Fluke 101 provide ±0.5% accuracy for reliable readings.

Why do my rechargeable AAA batteries show different voltages after the same charging cycle?

Voltage variations indicate aging differences between cells. Factors include:

- Internal resistance variations (new: 50mΩ vs aged: 200mΩ)

- Electrolyte depletion in older cells

- Inconsistent contact resistance in charger slots

For devices using multiple batteries, always group cells within 0.03V to prevent reverse charging damage.

How does temperature affect rechargeable AAA battery voltage?

Temperature significantly impacts voltage performance:

| Condition | Voltage Change | Capacity Impact |

|---|---|---|

| 0°C (32°F) | -15% | -30% |

| 25°C (77°F) | Baseline | 100% |

| 45°C (113°F) | +5% | -20% lifespan |

Premium batteries like Eneloop Pro handle temperature extremes better than standard NiMH cells.

Can I mix rechargeable and alkaline AAA batteries in the same device?

Absolutely not. Mixing 1.2V NiMH with 1.5V alkalines creates dangerous imbalances:

- Alkalines overwork trying to “charge” the NiMH cells

- Voltage differentials cause rapid discharge

- Risk of leakage and thermal runaway increases

This practice voids warranties on many electronic devices and poses fire hazards in high-drain applications.

How often should I check my rechargeable AAA batteries’ voltage?

Recommended voltage check frequency depends on usage:

- Critical devices (medical/safety): Before each use

- High-drain electronics: Weekly

- Low-drain devices: Monthly

- Storage: Every 3 months

Smart battery organizers like the Nitecore F1 can automate voltage tracking and record historical data.

What voltage indicates a rechargeable AAA battery needs replacement?

Replace batteries when they:

- Can’t reach 1.35V after full charge

- Drop below 1.1V under 50% load current

- Show >0.1V difference from new condition

- Take 3+ hours longer to charge

Industrial standards typically retire batteries after 20% voltage degradation from original specs.

Are lithium AAA batteries better than NiMH for voltage stability?

Lithium-ion 14500 cells (3.7V) offer superior voltage stability but require voltage regulators for 1.5V devices. New lithium ferrophosphate (LiFePO4) AAA batteries provide 1.5V nominal voltage with flatter discharge curves than NiMH, but cost 3x more. For most consumers, high-quality NiMH like Panasonic Eneloop Pro offer the best balance of voltage stability and value.