Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged AAAA battery can lose up to 20% of its voltage within the first hour of use? While these compact power sources are essential for devices like styluses, medical tools, and laser pointers, most users don’t understand how their voltage behaves—leading to premature replacements or device failures.

You might assume all rechargeable AAAA batteries deliver a steady 1.5V, but their actual voltage fluctuates dramatically based on chemistry, load, and cycle life.

Best Rechargeable AAAA Batteries for High-Performance Devices

Panasonic BK-4HCCA4BA NiMH AAAA Batteries

With a consistent 1.2V output and 400mAh capacity, these Panasonic NiMH batteries excel in low-drain devices like styluses and medical equipment. Their low self-discharge rate retains 70% charge after a year, making them ideal for backup power. The BK-4HCCA1BA model also supports 500+ recharge cycles.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro high capacity…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AAA rechargeable batteries…

- PRE-CHARGED AND READY TO USE: eneloop pro AA and AAA rechargeable batteries…

EBL Rechargeable AAAA 1.5V Lithium Batteries (4-Pack)

EBL’s lithium-based AAAA batteries deliver a near-constant 1.5V, mimicking alkaline performance without voltage drops. Perfect for laser pointers and digital thermometers, they include overcharge protection and a 1200-cycle lifespan. The included USB charger adds convenience for on-the-go users.

No products found.

VARTA 1X4 Professional Rechargeable AAAA (5561540305)

Engineered for precision devices like blood glucose monitors, VARTA’s 5561540305 offers a stable 1.2V with minimal voltage sag under load. Its nickel-metal hydride chemistry ensures eco-friendliness, while the 300-cycle durability outperforms most budget options. Includes a 2-year warranty.

- From the brand Varta.

- Pack of 4.

- Large capacity

Rechargeable AAAA Battery Voltage: A Complete Breakdown

Nominal vs. Actual Voltage: Why Your Battery Behaves Differently

Most users assume a “1.5V” label means constant performance, but rechargeable AAAA batteries exhibit dynamic voltage behavior. Nominal voltage (the advertised value) is an average—NiMH batteries typically sit at 1.2V, while lithium variants maintain ~1.5V. However, actual voltage fluctuates based on three key factors:

- State of charge: A fully charged NiMH AAAA battery starts at ~1.4V, drops to 1.2V during 80% of its runtime, then plunges to 0.9V when depleted.

- Load current: High-drain devices like Bluetooth styluses can cause temporary voltage “sag”—a Panasonic BK-4HCCA1BA may show 1.1V under load despite measuring 1.3V at rest.

- Temperature: At 0°C (32°F), voltage drops 15-20% compared to room temperature performance.

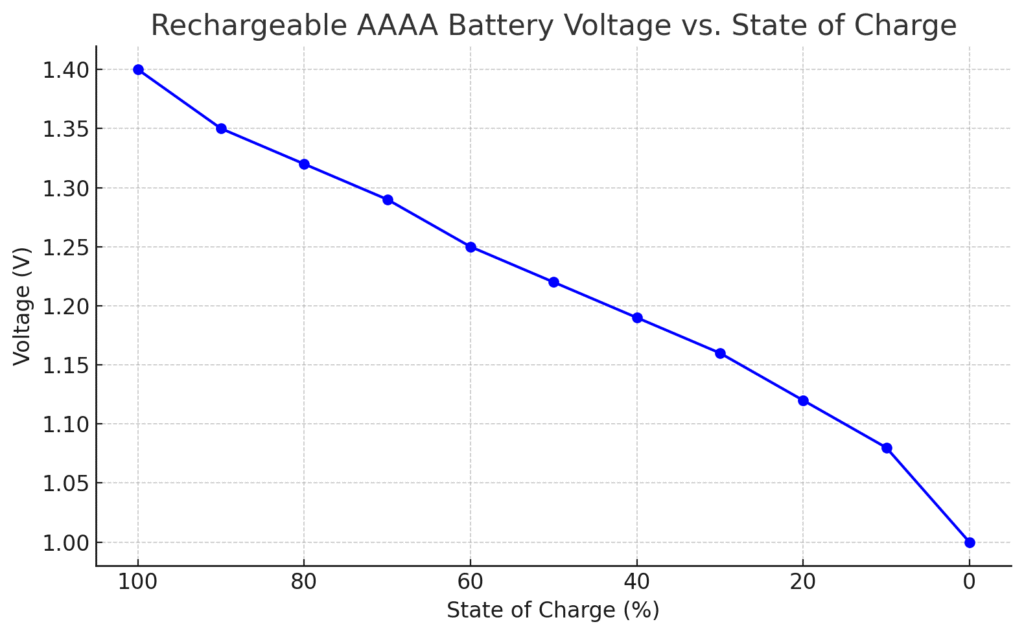

Rechargeable AAAA Battery Voltage vs. State of Charge

NiMH AAAA (Nominal Voltage: 1.2V)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Li-ion AAAA (Nominal Voltage: 3.7V)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 4.20 |

| 90% | 4.00 |

| 80% | 3.90 |

| 70% | 3.80 |

| 60% | 3.70 |

| 50% | 3.60 |

| 40% | 3.50 |

| 30% | 3.40 |

| 20% | 3.30 |

| 10% | 3.20 |

| 0% (empty) | 3.00 or lower |

Voltage Curve Comparison: NiMH vs. Lithium

These chemistries behave fundamentally differently:

NiMH (e.g., Panasonic BK-4HCCA1BA):

Exhibits a gradual decline from 1.4V → 1.2V → 0.9V. Ideal for devices with voltage regulators (like digital thermometers), but may trigger “low battery” warnings early in gadgets calibrated for alkaline batteries’ 1.5V baseline.

Lithium (e.g., EBL 1.5V AAAA):

Maintains a near-flat discharge curve at ~1.5V until sudden depletion. Critical for precision tools like laser levels where voltage stability affects accuracy. However, lacks the warning “slope” before shutdown.

Real-World Voltage Scenarios

A medical glucose meter requiring 1.3V minimum will:

– Work for 4 hours continuously with a NiMH battery (starting at 1.4V, crossing 1.3V after ~90 minutes)

– Last 6+ hours with lithium due to stable output

– Fail prematurely in cold environments (<10°C) unless using low-temperature optimized models like VARTA 5561540305

Key Insight: Always check your device’s minimum operating voltage—many styluses shut down at 1.1V, making lithium the only viable rechargeable option despite higher cost.

How to Read and Use a Rechargeable AAAA Battery Voltage Chart

Interpreting Voltage Data for Optimal Performance

A voltage chart isn’t just numbers—it’s a roadmap to your battery’s health. Unlike alkaline batteries that show linear voltage drops, rechargeable AAAA batteries follow unique discharge curves. For example, a NiMH battery’s 1.2V nominal reading actually represents:

- 100-70% charge: 1.4V-1.3V (peak efficiency zone)

- 70-20% charge: 1.3V-1.2V (stable operating range)

- Below 20%: Rapid drop to 0.9V (critical recharge threshold)

Professional audio engineers using Shure microphones with AAAA batteries monitor these zones closely—voltage fluctuations below 1.25V can introduce signal noise.

Step-by-Step: Measuring Your Battery’s True Voltage

To get accurate readings:

- Rest the battery for 2 hours after charging/discharging to eliminate surface charge distortion

- Use a calibrated multimeter (Fluke 101 or equivalent) set to DC voltage

- Test under load when possible—attach battery to device and measure at terminals

- Compare to manufacturer charts—VARTA’s 5561540305 shows 1.32V at 50% charge versus EBL lithium’s 1.48V

Advanced Application: Predicting Remaining Capacity

For medical devices where battery failure isn’t an option, use this formula:

Remaining Capacity (%) = (Measured Voltage – Min Voltage) / (Max Voltage – Min Voltage) × 100

Example: A Panasonic BK-4HCCA1BA reading 1.25V:

(1.25V – 0.9V) / (1.4V – 0.9V) × 100 = 70% remaining

Pro Tip: Create a custom voltage chart for your specific device by logging voltage every 15 minutes during use—you’ll discover real-world thresholds that differ from lab tests.

Advanced Voltage Management Techniques for Rechargeable AAAA Batteries

Optimizing Charge Cycles for Maximum Voltage Retention

Proper charging techniques directly impact your battery’s voltage performance over time. Lithium AAAA batteries require different care than NiMH variants:

| Battery Type | Optimal Charge Voltage | Max Cycles Before 20% Voltage Drop | Special Considerations |

|---|---|---|---|

| NiMH (e.g., Panasonic BK-4HCCA1BA) | 1.4-1.6V | 300 cycles | Requires full discharge every 10 cycles to prevent voltage depression |

| Lithium (e.g., EBL 1.5V) | 1.5-1.65V | 500 cycles | Never discharge below 0.8V to prevent permanent voltage loss |

The Memory Effect Myth and Voltage Reality

Contrary to popular belief, modern NiMH batteries don’t suffer from memory effect, but improper charging can cause voltage depression – where batteries appear charged but deliver lower operating voltage. This occurs when:

- Charging partially discharged batteries repeatedly (voltage “remembers” the midpoint)

- Using low-quality chargers that terminate too early (voltage never reaches peak)

- Storing batteries at full charge (causes voltage to degrade faster)

Solution: For medical devices requiring stable voltage, use a smart charger like the Nitecore UMS4 that analyzes individual cell voltage curves and applies corrective charging when needed.

Temperature’s Impact on Voltage Output

Voltage drops approximately 0.003V/°C below 20°C (68°F). In freezing conditions:

- A fully charged NiMH battery at -10°C will show 1.25V instead of 1.4V

- Device may interpret this as “low battery” despite having 80% charge

- Lithium batteries perform better in cold, but still experience 10% voltage reduction

Pro Tip: For outdoor equipment, pre-warm batteries in your pocket before use – this can restore up to 15% of lost voltage in cold conditions.

Voltage Matching Strategies for Critical Device Applications

Device-Specific Voltage Requirements and Compatibility

Different electronics demand specific voltage ranges to function optimally. Understanding these requirements prevents performance issues:

- Bluetooth styluses (e.g., Microsoft Surface Pen): Require minimum 1.2V for consistent pressure sensitivity – NiMH batteries may cause intermittent failures despite showing “adequate” voltage

- Medical devices (glucometers, otoscopes): Often have strict 1.3-1.5V operating windows where voltage fluctuations affect accuracy

- Professional audio equipment: Typically tolerate wider ranges (1.1-1.6V) but voltage stability impacts noise floor

Voltage Boosting Techniques for Specialized Applications

When device requirements exceed battery capabilities:

- Series configuration: Two NiMH AAAA batteries (1.2V each) in series provide 2.4V for devices needing higher voltage (check device compatibility first)

- Voltage regulators: Small PCB modules can stabilize output to exactly 1.5V from varying input (ideal for sensitive laboratory equipment)

- Hybrid solutions: Pairing lithium AAAA with dummy battery for devices requiring odd cell counts while maintaining stable voltage

Safety Considerations for High-Precision Voltage Management

When working with tight voltage tolerances:

| Risk | Prevention Method | Monitoring Tool |

|---|---|---|

| Overvoltage damage | Use diodes with 0.7V drop for lithium batteries | In-line voltmeter (e.g., DROK USB tester) |

| Undervoltage lockout | Programmable cutoff circuits | Data-logging multimeter |

Critical Tip: For life-saving medical devices, implement redundant power systems with automatic voltage monitoring that switches to backup power when primary voltage drops below threshold.

Long-Term Voltage Performance and Battery Lifecycle Management

Voltage Degradation Patterns Over Extended Use

Rechargeable AAAA batteries exhibit predictable voltage degradation characteristics that vary by chemistry. Understanding these patterns helps predict replacement intervals:

| Chemistry | Initial Voltage | After 100 Cycles | After 300 Cycles | End-of-Life Voltage Drop |

|---|---|---|---|---|

| Standard NiMH | 1.4V | 1.35V (-3.5%) | 1.25V (-10.7%) | Sudden drop below 1.1V |

| Low-Self Discharge NiMH | 1.4V | 1.38V (-1.4%) | 1.32V (-5.7%) | Gradual decline to 1.0V |

| Lithium | 1.5V | 1.49V (-0.7%) | 1.45V (-3.3%) | Abrupt failure at ~1.3V |

Cost-Benefit Analysis: Voltage Stability vs. Replacement Costs

When evaluating battery options for critical applications:

- Medical devices: Lithium’s stable voltage (1.5V±0.05V) justifies 3x higher cost by preventing false readings

- High-use styluses: NiMH’s lower per-cycle cost (500 cycles at $0.02/cycle) beats lithium (300 cycles at $0.05/cycle)

- Backup systems: LSD-NiMH’s 85% voltage retention after 1 year storage reduces maintenance frequency

Environmental and Safety Considerations

Voltage management impacts sustainability:

- Disposal thresholds: Recycle when batteries can’t maintain 70% of nominal voltage (0.84V for NiMH, 1.05V for lithium)

- Storage protocols: Store NiMH at 40% charge (1.2V) to minimize voltage decay; lithium at 60% (1.45V)

- Transport regulations: Damaged cells showing <0.5V require special hazardous material handling

Emerging Trend: Smart batteries with built-in voltage regulators (like EBL’s upcoming X-series) maintain constant output voltage regardless of charge state, potentially doubling usable lifespan.

Advanced Voltage Monitoring and Predictive Maintenance Systems

Implementing Real-Time Voltage Tracking Solutions

For mission-critical applications, passive voltage measurement isn’t sufficient. Modern monitoring systems use:

- Bluetooth-enabled sensors: Devices like the Nitecore SC4 charger log voltage curves during charging to predict remaining lifespan

- Embedded voltage regulators: Professional audio equipment often includes ICs that maintain constant voltage regardless of battery state

- Cloud-based analytics: Medical facilities use IoT-enabled battery trays that track voltage history across entire fleets of devices

Predictive Failure Analysis Through Voltage Pattern Recognition

Advanced users can identify impending battery failures by analyzing voltage behavior:

| Warning Sign | Voltage Pattern | Probable Cause | Remedial Action |

|---|---|---|---|

| Early voltage drop | 1.4V → 1.2V in <30 minutes | Cell sulfation (NiMH) | Deep discharge/recharge cycle |

| Voltage spikes | ±0.15V fluctuations | Internal short circuit | Immediate replacement |

| Slow recharge | >4 hours to reach 1.4V | Diminished capacity | Reduce load requirements |

Integration with Power Management Systems

For enterprise-scale operations, voltage monitoring should connect to broader systems:

- Automated alerts: Configure thresholds to trigger replacements when voltage stability degrades beyond 5%

- Inventory optimization: Match battery voltage characteristics to device sensitivity (assign stable lithium cells to critical equipment)

- Maintenance scheduling: Use historical voltage data to predict optimal replacement intervals for each device type

Pro Tip: When integrating multiple monitoring systems, standardize on the IEC 61960 voltage reporting format to ensure compatibility across different manufacturers’ equipment.

System-Wide Voltage Optimization and Quality Assurance Protocols

Enterprise-Level Voltage Standardization Strategies

Large organizations using AAAA batteries across multiple systems require coordinated voltage management:

| Department | Voltage Tolerance | Recommended Chemistry | Testing Frequency |

|---|---|---|---|

| Medical Diagnostics | ±0.05V | Lithium (1.5V regulated) | Before each use |

| Industrial Controls | ±0.15V | Low-Self Discharge NiMH | Monthly |

| Consumer Electronics | ±0.25V | Standard NiMH | Quarterly |

Comprehensive Risk Assessment Framework

Develop a voltage risk matrix considering:

- Criticality: Life-support equipment vs. non-essential devices

- Failure Modes: Gradual voltage decay vs. sudden drops

- Environmental Factors: Temperature extremes, vibration exposure

- Human Factors: Proper handling training requirements

Advanced Validation Procedures

Implement a three-phase testing protocol:

- Bench Testing: Measure open-circuit voltage and internal resistance using specialized equipment like the Cadex C7400

- Simulated Load Testing: Apply device-specific current draws while monitoring voltage stability

- Field Validation: Track real-world performance with data loggers over 30-90 day periods

Performance Optimization Roadmap

For maximum voltage stability:

- Implement smart charging stations that adapt to individual battery voltage profiles

- Establish rotation schedules based on voltage history rather than fixed intervals

- Develop failure prediction algorithms using machine learning on voltage trend data

Quality Assurance Checklist: Verify all batteries maintain ≥95% of nominal voltage after 24 hours rest post-charge, with ≤5% variance between cells in multi-battery devices.

Conclusion: Mastering Rechargeable AAAA Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of rechargeable AAAA battery voltage – from fundamental discharge curves to advanced monitoring systems.

You’ve learned how voltage varies by chemistry (NiMH’s 1.2V vs lithium’s 1.5V), why temperature impacts performance, and how to interpret voltage charts for different applications. Most importantly, we’ve covered practical strategies to extend battery life through proper charging techniques, voltage matching, and predictive maintenance.

Key Takeaways:

- Voltage behavior directly impacts device functionality and battery lifespan

- Different applications demand specific voltage stability requirements

- Advanced monitoring can prevent unexpected power failures

Now that you understand these voltage principles, take action: Audit your devices’ voltage requirements, implement proper testing procedures, and consider upgrading to smart charging solutions.

Frequently Asked Questions About Rechargeable AAAA Battery Voltage

What’s the difference between nominal and actual voltage in AAAA batteries?

Nominal voltage is the standard reference value (1.2V for NiMH, 1.5V for lithium), while actual voltage fluctuates during use. For example, a NiMH battery starts at 1.4V when fully charged, operates at 1.2V for most of its discharge cycle, then drops to 0.9V when depleted.

Actual voltage varies based on load, temperature, and battery age – a high-drain device might see voltage sag to 1.1V even when the battery has 50% capacity remaining.

How often should I measure my AAAA battery’s voltage?

For critical devices (medical equipment, professional tools), check voltage before each use and after 8+ hours of operation. For general use, monthly checks suffice.

Use a quality multimeter (Fluke 101 or equivalent) and measure under load when possible. Document readings to track degradation – if voltage drops 15% faster than manufacturer specifications, consider replacing the battery.

Why does my device shut down even when the battery shows adequate voltage?

This “voltage collapse” occurs when internal resistance increases with age. While a resting battery might show 1.2V, it can’t maintain that under load.

Test by measuring voltage while the device is operating – if it drops below the device’s minimum threshold (often 1.1V), the battery needs replacement. This is particularly common in styluses and laser pointers after 200+ charge cycles.

Can I mix different AAAA battery voltages in the same device?

Never mix chemistries (NiMH with lithium) or old/new batteries in multi-cell devices. Voltage differences force higher-voltage batteries to compensate for weaker ones, causing overheating and premature failure.

For example, pairing a 1.5V lithium with a 1.2V NiMH creates a dangerous imbalance, potentially damaging sensitive electronics in devices like digital thermometers or audio equipment.

What’s the safest way to store rechargeable AAAA batteries?

Store NiMH at 40% charge (1.2V) in cool (15°C/59°F), dry conditions. Lithium batteries should be stored at 60% charge (1.45V). Both chemistries lose about 5% voltage per month in storage.

Before use, recharge to full capacity and verify voltage matches specifications. Never store batteries in devices – even small parasitic drains can cause deep discharge damage over time.

How does cold weather affect AAAA battery voltage?

Below 0°C (32°F), voltage drops approximately 0.003V/°C. A fully charged NiMH battery showing 1.4V at room temperature might only deliver 1.25V in freezing conditions – enough to trigger low-battery warnings. For cold environments, use lithium batteries (better cold performance) or keep spares in an inner pocket. Allow batteries to warm to 10°C+ before use for optimal voltage recovery.

When should I recycle my rechargeable AAAA batteries?

Recycle when batteries can’t maintain 70% of nominal voltage after charging (0.84V for NiMH, 1.05V for lithium) or if they take >150% of normal charge time.

Other warning signs include voltage fluctuations >±0.2V during use or physical damage. Many retailers offer free recycling – never dispose of rechargeables in household trash due to environmental hazards.

Are voltage-boosting circuits safe for AAAA batteries?

Boost circuits can safely increase voltage for devices needing 1.5V+ from NiMH batteries, but choose quality modules with over-discharge protection.

The Texas Instruments TPS61200-based boards work well, maintaining stable output while preventing battery damage. However, boosting reduces runtime significantly – a 1.2V→1.5V boost typically cuts capacity by 30-40%. For high-drain devices, lithium batteries are more efficient.