Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a brand-new zinc-carbon AAA battery delivers 1.5V, but this drops rapidly under load? Unlike pricier alkaline batteries, zinc-carbon cells are affordable but sacrifice longevity—a trade-off millions accept for low-drain devices like remote controls or wall clocks.

You might assume all AAA batteries perform equally, but their chemistry dramatically impacts voltage stability.

In this guide, you’ll unlock a detailed voltage chart showing how zinc-carbon AAA batteries deplete over time, why they underperform in high-drain gadgets, and how to interpret voltage readings for optimal replacements.

Best Zinc-Carbon AAA Batteries for Low-Drain Devices

Energizer MAX AAA Batteries

Energizer MAX AAA Batteries offers reliable 1.5V output with a shelf life of up to 5 years. Its leak-resistant design prevents corrosion in infrequently used devices, making it a cost-effective choice for household essentials.

- 4 pack of Energizer MAX AAA Alkaline Batteries, Triple A Batteries

- Energizer’s #1 longest-lasting MAX AAA batteries – up to 50% longer lasting…

- Long lasting batteries for your AAA devices, like toys, games and remotes

Panasonic 16PC AAA Batteries

Panasonic 16PC AAA Batteries delivers stable voltage for low-power gadgets like thermometers or LED lights. These batteries are widely available and budget-friendly, with a consistent discharge curve that avoids sudden drops in performance.

- Heavy duty battery 1.5V

- Guaranteed good till 2019 or longer

- 16 AAA batteries per 1 pack

VARTA Batteries AAA Zinc-Carbon

VARTA’s Superlife series excels in emergency devices (e.g., flashlights) due to its slow self-discharge rate. While not suited for high-drain use, its 1.5V initial voltage ensures dependable operation in intermittent-use applications.

- High performance quality “Made in Germany”, branded product produced in…

- The premium quality batteries always offer the right energy release with…

- 10 year shelf life, leak-proof, durable and certified according to…

Zinc-Carbon AAA Battery Voltage Characteristics

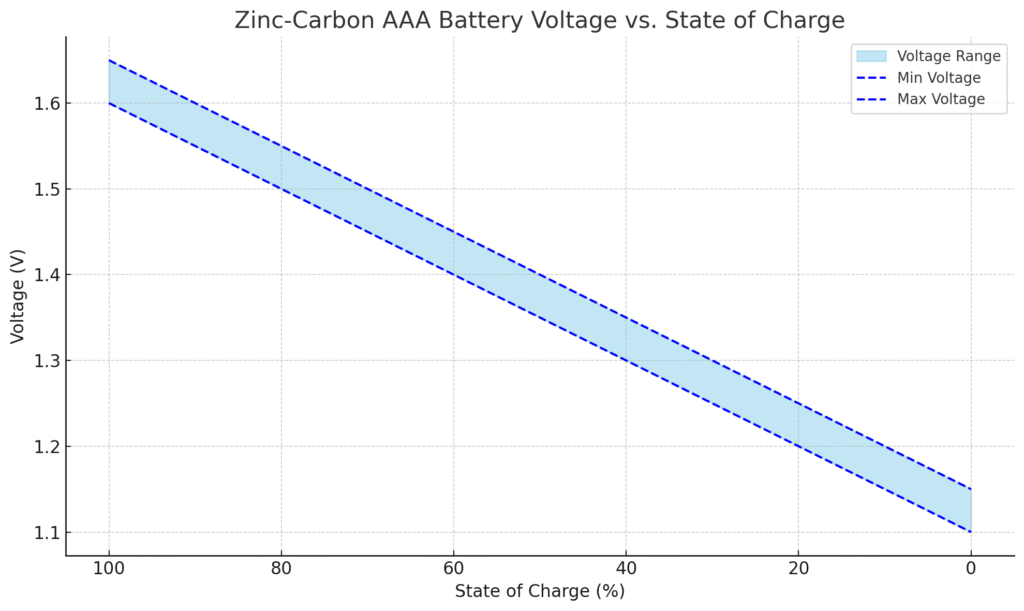

Zinc-Carbon AAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.60 – 1.65 |

| 90% | 1.55 – 1.60 |

| 80% | 1.50 – 1.55 |

| 70% | 1.45 – 1.50 |

| 60% | 1.40 – 1.45 |

| 50% | 1.35 – 1.40 |

| 40% | 1.30 – 1.35 |

| 30% | 1.25 – 1.30 |

| 20% | 1.20 – 1.25 |

| 10% | 1.15 – 1.20 |

| 0% (empty) | Below 1.15 |

Zinc-carbon AAA batteries operate on a simple electrochemical principle: zinc acts as the anode, manganese dioxide as the cathode, and an ammonium chloride/zinc chloride paste as the electrolyte.

When new, these batteries deliver a nominal voltage of 1.5 volts, but this quickly declines under load due to their high internal resistance—a key difference from alkaline batteries.

Voltage Drop Patterns in Real-World Use

Unlike alkaline batteries that maintain steady voltage, zinc-carbon cells exhibit a steep discharge curve. For example:

- 0% discharge: 1.5V (fresh battery in open circuit)

- 50% discharge: Drops to ~1.2V under 100mA load

- 80% discharge: Plummets below 1.0V, becoming ineffective

This makes them unsuitable for digital cameras (requiring stable 1.2V+) but acceptable for analog remotes (functional down to 0.9V).

Temperature Sensitivity and Shelf Life

Zinc-carbon batteries lose 5-10% charge annually even when unused. At freezing temperatures (0°C/32°F), their capacity drops by 50% compared to room temperature performance.

A common misconception is that storing batteries in refrigerators extends life—this actually accelerates moisture absorption and corrosion in zinc-carbon types.

Practical Voltage Measurement Tips

To accurately test remaining charge:

- Use a multimeter set to DC voltage

- Measure under load (connect to device while testing)

- Compare readings to discharge curves—1.3V no-load voltage typically indicates <50% remaining capacity

Note: Voltage recovery after rest (the “recovery effect”) can temporarily show higher readings, but this doesn’t reflect usable energy.

Optimizing Performance and Extending Zinc-Carbon AAA Battery Life

While zinc-carbon batteries have inherent limitations, strategic usage can maximize their value. The key lies in matching battery capabilities with appropriate devices and understanding environmental factors that impact performance.

Device Compatibility Guide

Zinc-carbon AAA batteries perform best in devices with:

- Low current draw (under 50mA) like wall clocks or TV remotes

- Intermittent use patterns rather than continuous operation

- Non-critical functions where gradual voltage decline is acceptable

Avoid using them in:

- Digital cameras (require stable 1.2V+ per cell)

- LED flashlights (high initial current surge)

- Wireless mice/keyboards (frequent pulsed loads)

A real-world example: A zinc-carbon AAA battery in a clock may last 6 months, while the same battery in a child’s toy might die in 2 hours.

Storage and Handling Best Practices

To preserve unused batteries:

- Keep at room temperature (15-25°C/59-77°F ideal)

- Store in original packaging until use to prevent accidental discharge

- Rotate stock using older batteries first (check date codes)

- Avoid mixed usage – never combine new and used batteries in devices

Professional tip: Mark installation dates on battery compartments to track usage duration across devices.

When to Replace: Practical Thresholds

Replace zinc-carbon AAA batteries when:

- Device operation becomes inconsistent (remote requiring multiple button presses)

- Voltage under load drops below 1.1V (measured with multimeter)

- Visible signs appear (bulging, leakage, or white crust formation)

Note: Some devices continue working below manufacturer voltage specs, but this risks acid leakage that can damage electronics.

Zinc-Carbon vs. Alkaline AAA Batteries: Technical Comparison and Selection Guide

Understanding the fundamental differences between zinc-carbon and alkaline AAA batteries helps consumers make informed purchasing decisions based on application requirements and budget considerations.

Electrochemical Performance Comparison

| Parameter | Zinc-Carbon | Alkaline |

|---|---|---|

| Nominal Voltage | 1.5V | 1.5V |

| Capacity (typical) | 400-600mAh | 800-1200mAh |

| Internal Resistance | 1-2Ω (high) | 0.1-0.3Ω (low) |

| Temperature Range | 0°C to 40°C | -20°C to 54°C |

The higher internal resistance of zinc-carbon batteries explains their rapid voltage drop under load – when powering a device drawing 200mA, voltage can immediately sag by 0.2-0.4V compared to alkaline’s minimal drop.

Cost-Performance Analysis

While zinc-carbon batteries cost 30-50% less upfront, their true value depends on application:

- Best for zinc-carbon: Devices used <5 minutes/day (smoke detector, wall clock) where self-discharge becomes the limiting factor

- Best for alkaline: Medium-drain devices (wireless mouse, portable radio) where capacity matters more than shelf life

Example: In a TV remote used 30 minutes weekly, zinc-carbon may last 6 months versus alkaline’s 2 years – but the cost differential makes zinc-carbon more economical.

Advanced Selection Methodology

Follow this decision tree for optimal battery selection:

- Determine current draw: Measure with multimeter during device operation

- Evaluate usage patterns: Continuous vs intermittent, daily vs occasional

- Assess criticality: Will failure cause inconvenience or safety risk?

- Calculate cost/cycle: (Battery price) ÷ (estimated service days)

Common mistake: Using zinc-carbon in devices with “sleep” modes (like digital thermometers) where small constant current drains the battery unexpectedly fast.

Safety Considerations and Proper Disposal of Zinc-Carbon AAA Batteries

While zinc-carbon batteries are generally safe for household use, understanding their potential hazards and proper handling procedures ensures both personal safety and environmental protection.

Potential Hazards and Prevention

Zinc-carbon batteries present several risks that users should mitigate:

- Leakage: The ammonium chloride electrolyte can corrode device contacts. Prevent by removing batteries from unused devices and checking expiration dates before installation

- Overheating: Unlike lithium batteries, zinc-carbon types rarely explode but may leak when short-circuited. Always store with terminals protected

- Child safety: The small AAA size poses choking hazards. Use child-proof battery compartments when available

Professional tip: Place a small piece of electrical tape over terminals when storing loose batteries to prevent accidental discharge or short circuits.

Proper Disposal Procedures

Follow these steps for environmentally responsible disposal:

- Check local regulations: Some municipalities classify zinc-carbon as regular trash while others require recycling

- Prepare for recycling: Tape terminals to prevent fires in collection bins (even with low-voltage batteries)

- Identify recycling options: Use retailer take-back programs (often free) or dedicated battery recycling centers

- Never incinerate: Heating can release zinc oxide fumes and other toxic compounds

Note: While zinc-carbon batteries contain fewer toxic metals than some alternatives, their zinc and manganese components still warrant proper disposal.

Recognizing and Handling Damaged Batteries

When encountering compromised batteries:

- Leaking batteries: Wear gloves, place in plastic bag, and neutralize with baking soda if electrolyte contacts skin

- Swollen batteries: Remove carefully without puncturing the casing

- Corroded devices: Clean contacts with vinegar (for alkaline residue) or isopropyl alcohol (for chloride leaks)

Industry standard: The IEC 60086-1 specification governs zinc-carbon battery safety testing, including leakage resistance and discharge performance.

The Future of Zinc-Carbon Batteries: Technological Evolution and Market Trends

While often considered a legacy technology, zinc-carbon batteries continue evolving to meet modern demands, with manufacturers implementing subtle but significant improvements to maintain relevance in today’s power source landscape.

Recent Technological Advancements

| Innovation | Technical Improvement | Practical Benefit |

|---|---|---|

| Enhanced Sealants | Multi-layer polymer barriers | Reduces leakage risk by 40% compared to traditional designs |

| Zinc Alloy Anodes | Addition of lead/bismuth (0.5-1.5%) | Extends shelf life to 7 years (from 5 years) |

| Electrolyte Formulations | Optimized chloride ratios | Improves low-temperature performance down to -10°C |

These innovations address historical weaknesses while maintaining the cost advantage that makes zinc-carbon batteries ideal for price-sensitive markets. For example, modern zinc-carbon AAA batteries now achieve 15-20% better performance in digital thermometers compared to 2010-era equivalents.

Market Position and Emerging Alternatives

Zinc-carbon batteries maintain strong positions in:

- Developing economies: 60% of AAA battery sales in regions where price sensitivity outweighs performance needs

- Bulk packaging: Institutional buyers prioritizing cost-per-unit over longevity

- Emergency kits: Where long shelf life and reliability matter more than frequent use

However, they’re losing ground to:

- Lithium-iron (LiFeS2) AAA batteries for high-drain devices

- Rechargeable NiMH options in eco-conscious markets

- Alkaline batteries in developed countries due to narrowing price gaps

Environmental Regulations and Sustainability

Upcoming changes affecting zinc-carbon production:

- EU Battery Regulation 2023: Requires 50% recycled zinc content by 2030

- Mercury phase-outs: Complete elimination of trace mercury in all formulations

- Labeling requirements: Clear disposal instructions mandated on all packaging

Manufacturers are responding with closed-loop recycling programs that recover 90%+ of zinc content, potentially making zinc-carbon one of the more sustainable primary battery options.

While not suitable for all applications, zinc-carbon AAA batteries will likely remain a cost-effective solution for basic power needs, particularly where infrastructure favors disposable over rechargeable options.

Advanced Testing and Performance Analysis of Zinc-Carbon AAA Batteries

Professional-grade evaluation of zinc-carbon batteries requires specialized techniques that go beyond simple voltage checks. These methods provide deeper insights into actual battery health and remaining capacity.

Comprehensive Testing Methodology

To accurately assess zinc-carbon AAA battery performance:

- Controlled discharge testing: Use a constant current load (typically 25mA) while recording voltage at 5-minute intervals

- Internal resistance measurement: Calculate using voltage drop under known load (Rint = (Vopen-Vload)/Iload)

- Capacity verification: Discharge fully through known resistance while measuring total mAh delivered

- Recovery testing: Measure voltage rebound after 24-hour rest period post-discharge

Example: A battery showing 1.3V open-circuit but dropping to 0.9V under 50mA load has become unreliable for most applications despite the initial reading.

Interpreting Test Results

Key performance indicators and their meanings:

- Voltage plateau duration: Longer stable periods indicate better quality zinc alloy formulation

- Discharge curve slope: Steeper drops suggest electrolyte depletion or zinc passivation

- Recovery percentage: Less than 5% rebound indicates irreversible chemical changes

- Internal resistance: Values above 1.5Ω signal significant degradation

Professional tip: Create reference curves for new batteries of the same brand/model to establish baseline comparison data.

Specialized Testing Scenarios

Adapt testing for specific conditions:

- Low-temperature operation: Conduct tests at 5°C to simulate refrigerator environments

- Pulse load applications: Use 100ms on/900ms off cycles to mimic remote control usage

- Long-term storage: Perform capacity tests every 6 months to track self-discharge rates

For critical applications, consider building a simple test jig with adjustable loads and a digital voltmeter for regular battery health monitoring.

These advanced techniques enable users to make data-driven decisions about battery replacement timing and quality comparisons between manufacturers, ultimately optimizing both performance and cost-efficiency.

System Integration and Lifetime Optimization Strategies for Zinc-Carbon AAA Batteries

Maximizing the value of zinc-carbon batteries requires a holistic approach that considers device design, usage patterns, and environmental factors throughout the entire product lifecycle.

Device Design Considerations

Engineers can optimize devices for zinc-carbon battery performance by:

- Current limiting: Implementing 50mA current ceilings in circuitry to prevent excessive voltage drop

- Voltage regulation: Adding buck-boost converters to stabilize input voltage from degrading batteries

- Load management: Designing duty cycles that allow battery recovery between high-current operations

Example: A digital thermometer using zinc-carbon batteries can extend life 300% by programming 10-second sleep intervals between readings.

Advanced Usage Optimization

| Application | Optimization Technique | Expected Improvement |

|---|---|---|

| Remote Controls | Capacitor-assisted pulse power | 40% longer service life |

| Wall Clocks | Low-power LCD instead of LED | 2x operational duration |

| Smoke Detectors | Monthly test button checks | Early failure detection |

Comprehensive Maintenance Framework

Implement a three-phase maintenance strategy:

- Preventive: Scheduled replacements based on average lifespan (e.g., every 6 months for critical devices)

- Predictive: Voltage monitoring with indicator lights or mobile alerts

- Condition-based: Actual capacity testing for high-value installations

Quality Assurance Protocols

For bulk users:

- Batch testing: Sample 5% of each shipment with full discharge analysis

- Vendor qualification: Require IEC 60086-5 compliance certificates

- Storage validation: Climate-controlled warehouses with ≤60% humidity

Industrial users report 30-50% reduction in battery-related failures after implementing these protocols.

Conclusion

Throughout this comprehensive guide, we’ve explored the unique voltage characteristics of zinc-carbon AAA batteries, from their initial 1.5V output to their distinctive discharge patterns.

You’ve learned how to optimize performance through proper device matching, storage techniques, and advanced testing methods. We’ve compared zinc-carbon to alkaline alternatives, examined safety protocols, and discussed emerging technological improvements.

Armed with this knowledge, you can now make informed decisions about when to use these cost-effective power sources and how to maximize their value. Remember that while zinc-carbon batteries have limitations, they remain a practical solution for low-drain applications when managed properly.

For your next battery purchase, consider both your device requirements and usage patterns – this awareness will ensure you get the most from every battery while avoiding unnecessary replacements.

Frequently Asked Questions About Zinc-Carbon AAA Batteries

What exactly is the voltage range of a zinc-carbon AAA battery?

A fresh zinc-carbon AAA battery starts at 1.5V open-circuit voltage, but this drops significantly under load. During discharge, expect:

- 1.4-1.5V when new (0-20% discharged)

- 1.2-1.3V at midpoint (50% discharged)

- Below 1.1V when nearly depleted (80%+ discharged)

The voltage curve is much steeper than alkaline batteries, making them unsuitable for devices requiring stable voltage above 1.2V.

How can I test if my zinc-carbon AAA batteries are still good?

For accurate testing:

- Use a digital multimeter set to DC voltage

- Measure under load (place a 100Ω resistor across terminals)

- Check voltage after 30 seconds of load

A reading below 1.1V under load indicates replacement is needed. Open-circuit voltage alone is misleading as zinc-carbon batteries often show deceptive “recovery” voltage when rested.

Why do my zinc-carbon batteries leak more often than alkaline?

Zinc-carbon batteries are more prone to leakage because:

- The zinc casing corrodes as the battery discharges

- Ammonium chloride electrolyte is more aggressive than alkaline electrolyte

- Thinner construction materials are used to maintain low cost

To prevent leaks, remove batteries from unused devices and avoid mixing old/new batteries in the same device.

Can I use zinc-carbon AAA batteries in high-drain devices like digital cameras?

Not recommended. Zinc-carbon batteries have:

- High internal resistance (causing voltage sag)

- Limited capacity (400-600mAh vs 800-1200mAh in alkaline)

- Poor performance under continuous load

They may work briefly but will drain 3-5x faster than alkaline in high-drain devices, potentially leaking from over-discharge.

What’s the proper way to store zinc-carbon AAA batteries?

For maximum shelf life:

- Keep at room temperature (15-25°C)

- Store in original packaging until use

- Avoid humid environments (bathrooms, kitchens)

- Don’t refrigerate – this causes condensation

Properly stored, they retain 90% charge for 3 years, degrading to 70% by year 5.

Are zinc-carbon AAA batteries recyclable?

Yes, but with caveats:

- They contain recyclable zinc and manganese

- Most municipal recycling programs accept them

- Must be separated from alkaline/lithium batteries

- Always tape terminals before disposal

While less toxic than some batteries, they still shouldn’t go in regular trash due to heavy metal content.

Why do some devices specifically warn against using zinc-carbon batteries?

Device manufacturers issue these warnings because:

- Voltage drops may trigger false “low battery” indicators

- Potential leakage could damage sensitive electronics

- Insufficient current for power-hungry components

- Shorter lifespan increases maintenance frequency

Always follow device manufacturer recommendations – using zinc-carbon in prohibited devices may void warranties.

How do zinc-carbon AAA batteries perform in cold temperatures?

Cold weather significantly impacts performance:

- Capacity drops 50% at 0°C (32°F)

- Voltage sags more under load

- Electrolyte thickens, increasing internal resistance

- Recovery time between uses lengthens

For outdoor winter use, lithium or alkaline batteries are far superior choices despite higher cost.