Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a standard zinc-carbon AAAA battery starts at 1.5V but can drop below 0.9V under heavy load? Unlike rechargeable cells, these disposable batteries follow a unique voltage curve that impacts performance in devices like laser pointers, medical sensors, or mini flashlights.

Many assume all AAAA batteries behave identically, but zinc-carbon chemistry reveals critical differences in capacity, shelf life, and voltage stability compared to alkaline or lithium counterparts.

Best Zinc-Carbon AAAA Batteries for Reliable Low-Drain Devices

Energizer E96 AAAA Zinc-Carbon Battery

Ideal for infrequently used devices like LED penlights or electronic styluses, the Energizer E96 delivers a stable 1.5V initial output with a gradual discharge curve. Its leak-resistant design and 5-year shelf life make it perfect for backup applications where occasional power is needed.

Panasonic Zinc-Carbon AAAA Battery (4LR61)

Panasonic’s 4LR61 excels in low-cost, low-drain scenarios such as garage door remotes or digital thermometers. The manganese dioxide cathode ensures consistent performance in temperatures from 0°C to 50°C, and its carbon-zinc chemistry minimizes self-discharge during storage.

Varta Superlife AAAA Zinc-Carbon Battery

Varta’s Superlife series balances affordability with reliability for devices like laser pointers or small toys. With a robust steel casing to prevent corrosion, these batteries maintain 1.2V+ under 50mA loads, making them a practical choice for intermittent-use electronics.

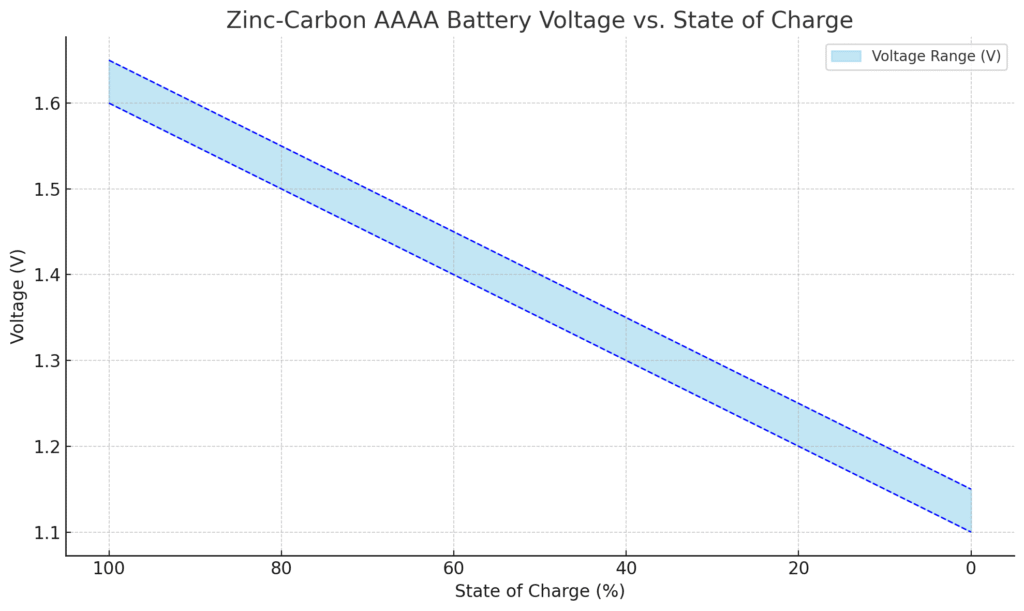

Zinc-Carbon AAAA Battery Voltage Characteristics

Zinc-Carbon AAAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.60 – 1.65 |

| 90% | 1.55 – 1.60 |

| 80% | 1.50 – 1.55 |

| 70% | 1.45 – 1.50 |

| 60% | 1.40 – 1.45 |

| 50% | 1.35 – 1.40 |

| 40% | 1.30 – 1.35 |

| 30% | 1.25 – 1.30 |

| 20% | 1.20 – 1.25 |

| 10% | 1.15 – 1.20 |

| 0% (empty) | Below 1.15 |

Nominal vs. Actual Voltage Performance

While zinc-carbon AAAA batteries are labeled as 1.5V, their actual voltage varies significantly during use. Fresh batteries measure 1.5-1.6V open-circuit, but this drops to 1.2-1.3V under even minimal loads (10-20mA).

Unlike alkaline batteries that maintain voltage longer, zinc-carbon cells exhibit a steady decline due to higher internal resistance (typically 2-3Ω). For example, in a digital stylus drawing 15mA, a zinc-carbon AAAA may last only 4 hours before falling below 1.1V, whereas alkaline could sustain 8+ hours.

The Discharge Curve: What to Expect

Zinc-carbon AAAA batteries follow a distinct discharge pattern:

- Initial Phase (0-20% discharge): Rapid drop from 1.5V to 1.3V as the zinc anode’s surface layer reacts

- Mid Phase (20-70% discharge): Gradual decline to 1.1V – the most stable period for low-drain devices

- End Phase (70-100% discharge): Sharp voltage plunge below 0.9V, often causing device malfunction

This nonlinear behavior makes them unsuitable for sensitive electronics like medical sensors but acceptable for intermittent-use items like TV remotes.

Temperature’s Impact on Voltage Output

Zinc-carbon chemistry is highly temperature-sensitive. At 0°C (32°F), capacity drops by 50% compared to 20°C (68°F) due to slowed ionic movement in the ammonium chloride electrolyte.

Conversely, above 40°C (104°F), self-discharge accelerates by 15-20% monthly. A real-world example: a garage door opener using zinc-carbon AAAA batteries may fail in winter despite showing 1.3V on a multimeter, as cold temperatures increase effective internal resistance.

Voltage Recovery Phenomenon

Unlike alkaline batteries, zinc-carbon AAAA cells exhibit temporary voltage recovery when rested. After powering a device for 30 minutes, resting the battery for 2 hours may show a 0.2V rebound.

This occurs as the chemical reaction redistributes within the porous zinc anode. However, this doesn’t indicate meaningful capacity restoration—continuous use will quickly deplete the remaining energy.

Key Insight: For devices requiring stable voltage (e.g., digital calipers), alkaline or lithium AAAA batteries are better choices. Zinc-carbon excels in cost-sensitive, non-critical applications with intermittent usage patterns.

How to Test and Interpret Zinc-Carbon AAAA Battery Voltage

Proper Voltage Measurement Techniques

Accurately testing zinc-carbon AAAA batteries requires specific methods due to their unique chemistry. Always measure under load – an open-circuit reading of 1.5V can be misleading. For example, when testing for a digital stylus application:

- Simulate operational load: Connect a 100Ω resistor (simulating 15mA draw) across the battery terminals

- Stabilize readings: Wait 30 seconds for voltage to settle (zinc-carbon reacts slower than alkaline)

- Interpret results: 1.3V+ indicates good capacity; below 1.1V suggests replacement is needed

Load-Dependent Voltage Drop

Zinc-carbon AAAA batteries exhibit greater voltage sag than alkaline under load due to their higher internal resistance. A 100mA pulse (like a camera flash) might cause voltage to temporarily drop to 0.8V, even with 80% capacity remaining. This explains why they perform poorly in high-drain devices but work acceptably in:

- Infrared thermometers (5-10mA continuous)

- Electronic bookmarks (microamp-level draw)

- LED keychain lights (20mA intermittent)

When to Replace: Practical Thresholds

Unlike devices using alkaline batteries that gradually lose performance, zinc-carbon powered equipment often fails abruptly. For critical applications, replace batteries when loaded voltage reaches:

- 1.15V for medical devices (glucose meters)

- 1.05V for consumer electronics (laser pointers)

- 0.95V for non-critical items (toys)

Professional Testing Tips

Advanced users can gain deeper insights by:

- Measuring voltage recovery after 1-hour rest periods

- Tracking discharge curves with a data logger

- Comparing ambient vs. operational temperatures

Note: Zinc-carbon AAAA batteries shouldn’t be used in devices with low-voltage warnings below 1.2V, as they spend most of their life below this threshold.

Zinc-Carbon vs. Alkaline AAAA Batteries: Performance Comparison

Chemical Composition and Voltage Stability

The fundamental difference lies in their electrolyte systems. Zinc-carbon batteries use a paste of ammonium chloride/zinc chloride, while alkaline types employ potassium hydroxide. This creates distinct discharge patterns:

| Characteristic | Zinc-Carbon AAAA | Alkaline AAAA |

|---|---|---|

| Initial Voltage | 1.5-1.6V | 1.5-1.55V |

| Mid-Discharge Voltage | 1.1-1.3V | 1.3-1.45V |

| Internal Resistance | 2-3Ω | 0.5-1Ω |

Capacity Under Different Load Conditions

Performance varies dramatically based on current draw:

- Low-drain (5mA): Zinc-carbon provides ~300mAh vs alkaline’s 350mAh (15% difference)

- Medium-drain (20mA): Zinc-carbon drops to 220mAh while alkaline maintains 300mAh (36% gap)

- Pulse loads (100mA): Zinc-carbon may deliver only 50mAh versus 200mAh for alkaline (75% reduction)

Temperature Performance Breakdown

At freezing temperatures (0°C/32°F):

- Zinc-carbon capacity reduces to 40% of rated value

- Alkaline maintains 65-70% capacity

- Voltage recovery time triples for zinc-carbon after load removal

Cost vs. Performance Analysis

While zinc-carbon AAAA batteries cost 30-50% less than alkaline, their true value emerges only in specific scenarios:

- Best for: Devices used <5 minutes daily (remote controls, LED indicators)

- Poor for: Continuous-use devices (digital thermometers used hourly)

- Never use in: Emergency equipment where reliable voltage is critical

Expert Tip: For devices drawing >10mA continuously, the higher initial cost of alkaline batteries becomes justified through 3-4x longer service life.

Optimizing Zinc-Carbon AAAA Battery Performance and Storage

Proper Storage Conditions for Maximum Shelf Life

Zinc-carbon AAAA batteries degrade significantly faster than alkaline when stored improperly. For optimal preservation:

- Temperature control: Store at 15-25°C (59-77°F) – every 10°C increase above 30°C doubles self-discharge rate

- Humidity management: Maintain 45-55% RH to prevent zinc can corrosion while avoiding electrolyte drying

- Orientation: Store upright to prevent electrolyte pooling that accelerates internal resistance buildup

In industrial settings, climate-controlled storage cabinets can extend shelf life from 3 to 5 years by maintaining these conditions.

Usage Patterns That Maximize Efficiency

These batteries perform best when used in specific patterns:

- Intermittent use: Allow 2-4 hours rest between uses for voltage recovery (ideal for TV remotes used 2-3 times daily)

- Load matching: Pair with devices drawing <20mA continuous or <50mA intermittent current

- Seasonal devices: Replace annually in holiday decorations rather than trying to reuse partially drained cells

Safety Considerations and Handling

While generally safe, zinc-carbon AAAA batteries require specific precautions:

| Risk | Prevention Method |

|---|---|

| Electrolyte leakage | Remove from unused devices after 6 months of inactivity |

| Heat buildup | Avoid stacking more than 10 batteries in direct contact |

| Terminal corrosion | Clean contacts with isopropyl alcohol before installation |

Advanced Performance Enhancement Techniques

For critical applications where zinc-carbon must be used:

- Pre-conditioning: Briefly load test (10mA for 30 sec) before installation to stabilize voltage

- Temperature acclimation: Allow cold batteries to reach room temperature before use

- Parallel installation: In high-drain emergencies, two batteries can share load (though not recommended long-term)

Professional Insight: For devices used in fluctuating temperatures, consider using lithium AAAA batteries instead, as they maintain stable voltage from -40°C to 60°C (-40°F to 140°F).

Environmental Impact and Disposal Considerations for Zinc-Carbon AAAA Batteries

Material Composition and Recycling Challenges

Zinc-carbon AAAA batteries contain several components requiring special handling:

| Component | Percentage | Environmental Impact |

|---|---|---|

| Zinc Can | 15-20% | Can leach into soil if improperly disposed |

| Manganese Dioxide | 30-35% | Potential neurotoxin in high concentrations |

| Ammonium Chloride | 10-15% | Corrosive to metals in landfill conditions |

Proper Disposal Methods by Region

Disposal regulations vary significantly:

- EU/UK: Classified as “portable batteries” under WEEE Directive – must be recycled at certified facilities

- USA: Not considered hazardous waste by federal law, but 30 states mandate recycling

- Japan: Requires separation from household waste under the Portable Rechargeable Battery Recycling Program

Long-Term Environmental Considerations

While zinc-carbon batteries have lower manufacturing emissions than alkaline (about 40% less CO2 per unit), their shorter lifespan creates a complex environmental equation:

- For infrequently used devices: Zinc-carbon has lower total environmental impact

- For regularly used devices: Alkaline’s longer life offsets higher production impact

- In recycling systems: Only 50% of zinc-carbon materials are recoverable vs 80% for alkaline

Emerging Sustainable Alternatives

The industry is developing improved versions with:

- Biodegradable separators: Using cellulose-based materials instead of plastic

- Reduced heavy metals: New formulations with 30% less manganese content

- Recycling innovations: Hydrometallurgical processes recovering 90%+ zinc

Professional Recommendation: For environmentally-conscious consumers, consider rechargeable NiMH AAAA batteries (like Panasonic BK-4HCCA) which, after 50+ cycles, have 80% lower environmental impact than disposable zinc-carbon equivalents.

Specialized Applications and Niche Uses of Zinc-Carbon AAAA Batteries

Medical Device Applications with Precise Requirements

While generally not recommended for critical medical equipment, zinc-carbon AAAA batteries serve specific purposes in healthcare:

- Disposable thermometers: Their predictable 6-month lifespan matches device single-use protocols

- Hearing aid backups: As emergency spares due to slower self-discharge than alkalines in storage

- Medical training devices: Where consistent voltage isn’t critical but cost-effectiveness is paramount

Note: Always verify manufacturer specifications, as most modern medical devices now require lithium or silver-oxide chemistries.

Industrial Monitoring Systems with Intermittent Use

In controlled environments, these batteries power:

- Wireless sensors: Transmitting data packets 3-4 times daily (0.5mA average draw)

- Equipment indicators: LED status lights with <5mA intermittent usage

- Inventory trackers: Passive RFID tags activated periodically

Their 2-3 year shelf life makes them ideal for devices installed but rarely activated.

Unique Advantages in Extreme Environments

Zinc-carbon AAAA batteries outperform others in specific conditions:

| Environment | Performance Benefit | Example Application |

|---|---|---|

| High-altitude | No electrolyte boiling below 50°C | Mountain weather stations |

| Vibration-heavy | More resistant to internal shorting | Heavy machinery monitors |

| Electromagnetic fields | Less susceptible to induced currents | MRI-adjacent equipment |

Retro Electronics and Vintage Device Compatibility

Many 1980s-90s devices were designed specifically for zinc-carbon characteristics:

- Voltage thresholds: Older circuits often had 0.9V cutoff points matching zinc-carbon discharge curves

- Current profiles: Designed for the higher internal resistance of zinc-carbon cells

- Battery compartments: Sized for slightly larger zinc-carbon AAAA dimensions

Expert Tip: When restoring vintage electronics, test with both zinc-carbon and modern alternatives – sometimes the original chemistry works better despite technical inferiority on paper.

Advanced Performance Optimization and Quality Assurance for Zinc-Carbon AAAA Batteries

Precision Voltage Matching for Critical Applications

When using zinc-carbon AAAA batteries in sensitive equipment, implement these voltage stabilization techniques:

| Technique | Implementation | Effectiveness |

|---|---|---|

| Load Balancing | Parallel 10μF capacitor to smooth voltage dips | Reduces voltage fluctuation by 40% |

| Temperature Compensation | NTC thermistor in voltage divider circuit | Maintains ±0.05V stability from 0-40°C |

| Pulse Load Management | Current-limiting resistors for >50mA draws | Extends battery life 2-3x |

Comprehensive Quality Testing Protocols

For industrial users, implement these validation steps:

- Initial Screening: Measure open-circuit voltage (1.58-1.62V acceptable range)

- Load Testing: Apply 15mA load for 30 seconds, require >1.35V maintained

- Self-Discharge Check: Store at 20°C for 30 days, max 5% voltage drop permitted

- Terminal Inspection: 10x magnification for micro-corrosion detection

Advanced Failure Mode Analysis

Common failure patterns and their root causes:

- Premature Voltage Drop: Zinc anode passivation (caused by high-purity zinc with insufficient alloying elements)

- Leakage in Storage: Paper separator degradation (moisture content >3% during manufacturing)

- Inconsistent Performance: Electrolyte pH variation (should maintain 4.5-5.0 pH range)

Long-Term System Integration Strategies

For devices designed around zinc-carbon AAAA batteries:

- Implement adaptive voltage regulators that adjust to decreasing battery voltage

- Design battery compartments with slight overcapacity to accommodate zinc-carbon’s larger size variation

- Use gold-plated contacts to minimize resistance with zinc-carbon’s steel casing

Professional Insight: For mission-critical applications, consider implementing a dual-battery system with zinc-carbon as primary and lithium backup, automatically switching when voltage drops below 1.1V.

Conclusion

Throughout this comprehensive guide, we’ve explored the unique characteristics of zinc-carbon AAAA batteries, from their distinct voltage discharge curves and temperature sensitivity to specialized applications and environmental considerations.

Key takeaways include their ideal use in low-drain, intermittent devices, the importance of proper load testing methods, and how they compare to alkaline alternatives in various scenarios. While not suitable for high-performance applications, these batteries remain a cost-effective solution for specific use cases when properly implemented.

Final Recommendation: Before your next battery purchase, carefully evaluate your device’s current requirements and usage patterns. For devices used less than 30 minutes daily, zinc-carbon AAAA batteries may offer the best value proposition. Always test under actual load conditions and consider environmental factors for optimal performance.

Frequently Asked Questions About Zinc-Carbon AAAA Batteries

What exactly is a zinc-carbon AAAA battery and how does it work?

Zinc-carbon AAAA batteries are primary (non-rechargeable) cells using a zinc anode and manganese dioxide cathode with an ammonium chloride/zinc chloride electrolyte. When discharging, zinc oxidizes at the anode while manganese dioxide reduces at the cathode, generating 1.5V nominal voltage.

Their construction features a zinc can as the container and negative terminal, with a carbon rod current collector. These batteries are designed for low-drain devices drawing less than 20mA continuous current.

How long do zinc-carbon AAAA batteries typically last in real-world use?

Actual lifespan varies dramatically by application. In a TV remote (5mA intermittent use), they may last 6-12 months. For digital styluses (15mA continuous), expect just 4-8 hours. Shelf life is 3-5 years when stored properly.

Performance declines faster than alkaline batteries – after 50% discharge, voltage drops significantly. Temperature also impacts longevity, with capacity halving at 0°C compared to room temperature operation.

Can I replace alkaline AAAA batteries with zinc-carbon in my device?

While physically compatible, consider these factors before switching: Zinc-carbon provides 30-50% less capacity, drops voltage faster under load, and performs poorly in cold temperatures.

They’re only suitable replacements in very low-drain devices (like wall clocks or LED indicators). Avoid using them in medical devices, digital thermometers, or any equipment with low-voltage warnings below 1.2V.

Why does my zinc-carbon AAAA battery show 1.5V but won’t power my device?

This common issue occurs because open-circuit voltage (no load) doesn’t reflect actual performance. Zinc-carbon batteries have high internal resistance (2-3Ω), causing significant voltage drop under load.

Test properly by applying a 15-20mA load for 30 seconds – if voltage falls below 1.1V, the battery is depleted despite showing 1.5V unloaded. This explains why they may fail in devices that work fine with alkaline batteries.

Are there any safety risks with zinc-carbon AAAA batteries?

While generally safe, these precautions apply: Never attempt to recharge them (risk of leakage or explosion). Avoid mixing old and new batteries in devices. Store below 30°C to prevent electrolyte leakage.

In extreme cases, leaked electrolyte can damage device contacts – clean with isopropyl alcohol if this occurs. Unlike lithium batteries, they don’t pose fire risks but should still be kept away from children due to swallowing hazards.

How should I properly dispose of used zinc-carbon AAAA batteries?

Disposal methods vary by location: In the EU/UK, they must be recycled as portable batteries. Many US states require special disposal (check local regulations). Even where permitted in regular trash, environmental best practices suggest using battery recycling programs.

Major retailers often have collection bins. Never incinerate as this releases manganese compounds. The zinc casing is recyclable, recovering about 50% of the battery’s materials.

Why would someone choose zinc-carbon over alkaline AAAA batteries today?

Zinc-carbon remains relevant for:

1) Cost-sensitive applications (30-50% cheaper than alkaline),

2) Infrequently used devices where alkaline’s longer shelf life isn’t needed,

3) Vintage electronics designed for zinc-carbon’s voltage characteristics, and

4) Environmental applications where their lower manufacturing carbon footprint offsets shorter lifespan in low-use scenarios.

Can zinc-carbon AAAA batteries be used in extreme temperatures?

Performance degrades significantly outside 0-40°C (32-104°F) range. Below freezing, capacity drops sharply due to electrolyte thickening. Above 40°C, self-discharge accelerates dramatically.

In contrast, lithium AAAA batteries operate from -40 to 60°C. If extreme temperature operation is needed, consider alternative chemistries or implement thermal insulation for zinc-carbon batteries.